Welcome to MobileTraining.ie

Lock Out Tag Out (LOTO) Equipment

1. Isolation Points

All isolation points for hazardous energy must:

- provide reliable isolation of the energy source

- be capable of being locked in the isolating position

- clearly identify the state of the isolation device (e.g. ON/OFF, OPEN/CLOSED)

- be located as close to the machine as feasible

Each isolation point must also be labeled to identify both its function and the equipment that it isolates.

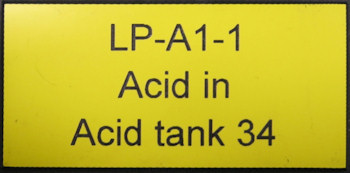

The label below indicates the following information at the isolation point:

LP-A1-1 = Loto point number dedicated to LOTO point

Acid In = Indicates the hazardous energy the LOTO point is isolating

Acid Tank 34 = The machinery/ piece of equipment

2. Locks

Each authorised and affected worker must have access to a lock for personal use. Each LOTO lock must be unique, identifiable and require a different key. Only one key shall be supplied with each lock. In case of the key for a particular lock being lost, the lock must be replaced. Locks are colour coded in the following way:

Red= Authorised worker locks out the equipment with the red locks in combination with an isolation tag attached to each lock and also attaches the red lock and personal danger tag which personalizes the lock to secure the lockbox. For simple lockouts the trained affected worker also uses the red lock in combination with their Personal danger tag to lock out the equipment.

Keyed Alike padlocks= In some case these locks are keyed alike in that one key opens numerous locks however this key is unique to these set of locks. These are used in complex lockouts where numerous sources of energy need to be locked out at any one time.

Yellow = Affected worker places his yellow (if he is not the person who locked out the simple equipment) lock on the Multilock hasp (1 or 2 lock points) or the lockbox (Multiple lockout points)prior to working on the equipment.

Orange = A contractor working as an Affected worker places his orange lock on the Multilock hasp (1 or 2 lock points) or the lockbox (Multiple lockout points) prior to working on the equipment. It is the responsibility of the need manager/designate to ensure that the contractor puts his lock & isolation tag on the lockbox or multilock hasp.

Purple = When a lock out crosses over a shift a transition purple lock is placed on the lockbox by the authorised worker. He then removes his own red lock and PDT. He hands the key of the purple lock over to the next authorised worker coming on or places the key in a designated secure location in the workshop. The next authorised worker coming on then checks the machine and place a red lock with his PDT on the lockbox when he is satisfied that the equipment has been locked out correctly and then removes the purple lock.

Caddy = A caddy is used to carry locks to their destination. It is especially useful for keyed alike locks where (X) amount of locks are required to lock out a specific machine. There is only (X) amount of holes punched in the caddy to reflect the amount of locks required for that lock out.The one key used to open these locks is attached to the caddy. A Caddy can carry up to a maximum of 12 locks.

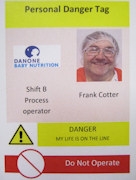

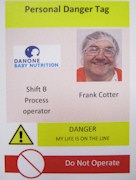

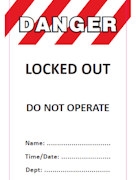

3. Personal Danger Tags (PDT)

Each authorised and affected worker must be issued with at least one PDT. Most will be issued with 4-5 depending on their area and job.

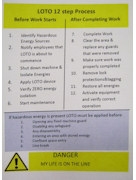

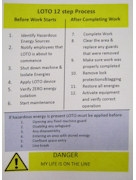

A PDT is a personally issued tag, with information about the owner which personalizes the lock it is attached to. It also has on the rear of the tag the 12 step process which must be followed each time a lock out occurs. Each PDT is unique and will clearly identify the owner of that tag.

The PDT in combination with a red lock (Authorised Worker) which is applied to the lockbox or multilock hasp indicates that this person has locked out the machine.

The PDT in combination with a yellow lock (Affected Worker) which is applied to the lockbox or multilock hasp indicates that this person is working on the machine.

The PDT in combination with an orange lock (contractor) which is applied to the lockbox or multilock hasp indicates that this person is working on the machine.

PDTS will be held in various accessible locations across the site for ease of access.

4. Isolation Tag

An Isolation tag is applied to each lock-out point of the equipment accompanied by a red lock, to indicate that isolation point has been isolated and is not operational. The isolation tags are only used when a lock box is used. The PDT is applied directly to the isolation points where there are 2 or less isolation points.

An isolation tag is also attached to the transition lock by the authorised worker when attaching the lock to the lockbox detailing the time and date the transition lock was applied and by whom and also from which shift it is being transitioned to and from. Periodic contractors who have not been issued with a PDT will use an isolation tag recording their name, date, their contact # and their company and attach it to the orange lock which they have attached to the lockbox.

5. Lock-Out Box

A lock-out box is used to store keys to multiple equipment locks, used when a machine has multiple energy sources. The lock-out box is then locked with the lock and PDT of each person who will work on the machine regardless of the work being carried out.

A red lock & PDT combination attached to a lock box indicates that the equipment has been locked out by the person whose photo is on the PDT.There will only be ever be only on red lock & PDT on the lockbox.

The PDT in combination with a yellow lock (Affected Worker) which is applied to the lockbox or multilock hasp indicates that this person is working on the machine.There can be multiple yellow locks & PDTs on the lockbox, one for each worker working on the locked out equipment.

The isolation tag or PDT in combination with an orange lock (contractor) which is applied to the lockbox or multilock hasp indicates that this person is working on the machine. There can be multiple orange locks & PDTs/isolation tags on the lockbox, one for each worker working on the locked out equipment.

6. Multi-Padlock Hasp

A Multi-Padlock Hasp is used so that a number of workers may apply their locks and personal danger tags (PDT) to the isolation points of a simple machine.This is usually used in combination with a red lock & PDT when there are 2 or less isolation points on the equipment. If another person is working on the equipment he/she will place a yellow lock and PDT on each hasp or in the case of a contractor an orange lock & PDT/isolation tag.

7. LOTO Stations

LOTO Stations will be established at appropriate, easily-accessible centralised locations. Where practicable, it is preferable to have a designated LOTO Station for each local work area. LOTO stations will provide a convenient storage location for locks, tags and other devices and act as a visual reminder of the necessity for LOTO compliance and the requirements of the LOTO program.

8. Other Energy-Isolating Devices

In addition to padlocks, other energy isolation devices will be kept available as required. Each device should be capable of being locked with a padlock. Each local LOTO station will contain adequate numbers and types of LOTO equipment.